I had a major quadcopter crash a few weeks ago – and it wasn’t due to my dodgy flying skills. One of my propellers broke in mid-air; one blade snapped off from a prop at the hub. The prop was one of two new bright orange coloured ones I’d bought to help keep track of the direction of the aircraft, which worked very well for me until it crashed. Looking more closely at these new orange props I now notice that they are much thinner where they attach to the hub. My other props thicken out as they approach the hub making them much stronger. The orange ones are much weaker – bending them quickly results in white crease lines at the hub, which doesn’t happen with my black ones. Lesson learned, don’t buy cheap props (actually, they weren’t any cheaper, so the lesson is to understand how to recognise crap props).

At the time the prop snapped, I was about 20 metres up in the air, traveling horizontally at quite some speed. When it broke, which made a “ping” sound, I panicked and dropped the throttle and then realised that was wrong and throttled back up to try and cushion the landing. I’m not really sure to what extent that helped, but it hit the grassy ground hard. I was flying it in a field near my house and was prevented from immediately retrieving it by a group of curious horses that went to investigate this UFO crash landing site. Luckily they decided against trampling or eating it and eventually lost interest.

It was still powered up when I got to it, though unarmed. Annoyingly I’d decided against flying with the camera this time so didn’t have any dramatic footage of the accident.

The battery looks too badly damaged to use. It’s not quite punctured, but it’s bashed up and misshapen. I may try recharging it out of curiosity, but I expect it to set on fire, explode or quantum leap or something – who knows with these lipo things. Quantum lipo. A friend has loaned me two new batteries, which are higher capacity (3900mAh) but weigh more – so we’ll see how that works out for performance and flight time.

A couple of the other props got damaged, but the motors, ESCs, and controller stuff seem all fine.

The two arms where it hit the ground were bent quite badly.

Rebuild

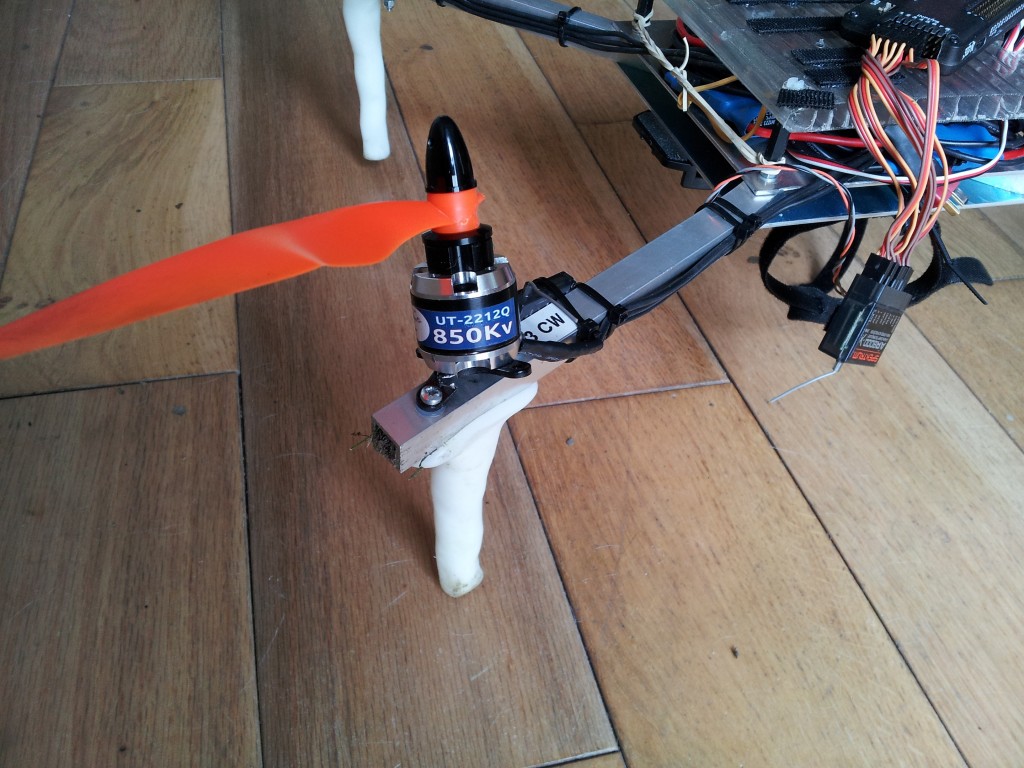

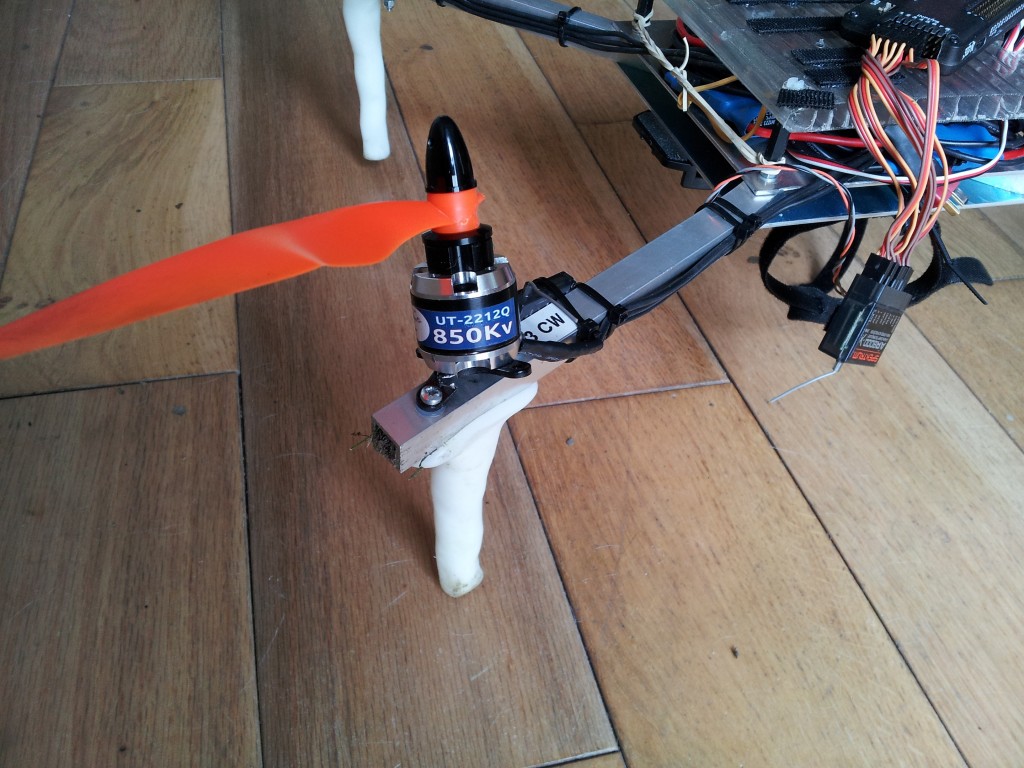

It’s taken me about a month to get around to it, but I’ve finally rebuilt it. The new frame is pretty much the same design as before but with a couple of minor modifications. I mounted the arms less closely to the middle of the base, so there is more space for cables, and I mounted the motors about 1cm closer to the end of the arms. So the result is that the motors are about 2-3cm further away from the base, which I expect to change the behaviour slightly and gives me more headroom between the props and the base – they were quite close before and prevented me from mounting some bits close to the edge of the base.

Since my first build I’ve acquired a power drill mounting and I built a wooden jig to keep the two bases in place, which meant I was able to drill holes much more accurately. I also drilled lots of extra holes which I knew would be handy, so more places to run cables and pass through tie-clips. It’s much tidier now.

Since my first build I’ve acquired a power drill mounting and I built a wooden jig to keep the two bases in place, which meant I was able to drill holes much more accurately. I also drilled lots of extra holes which I knew would be handy, so more places to run cables and pass through tie-clips. It’s much tidier now.

Lastly, in an effort to isolate vibration better, I put patches of neoprene where the arms are bolted to the base plates, and where the motors are bolted to the arms. The neoprene was an old laptop “skin” I cut up. I had to remove it from the motors as it meant they weren’t mounted perfectly square, so the craft was spinning a bit. I’m not really certain how effective this is as I don’t really have any data to back it up so it’s a bit cargo culting atm. I may experiment with this more scientifically at some point.

I bought some much sturdier carbon-fibre reinforced propellers too – I’ll write about my efforts to balance them properly later.

In summary, crashed it due to cheap propellers and I took the opportunity to rebuild the frame with some improvements. No horses were harmed.